Indoor light-activated titanium dioxide coating – made using chlorine chemistry – has antimicrobial properties

High-touch hospital surfaces such as doorknobs and faucet handles “are the secret network germs use to spread infections in hospitals. A new coating for stainless steel could stop them in their tracks,” suggests a new study (Chemical & Engineering News, February 20, 2019). The study, by researchers from New Zealand and France, was published in the Nature publication, Scientific Reports.

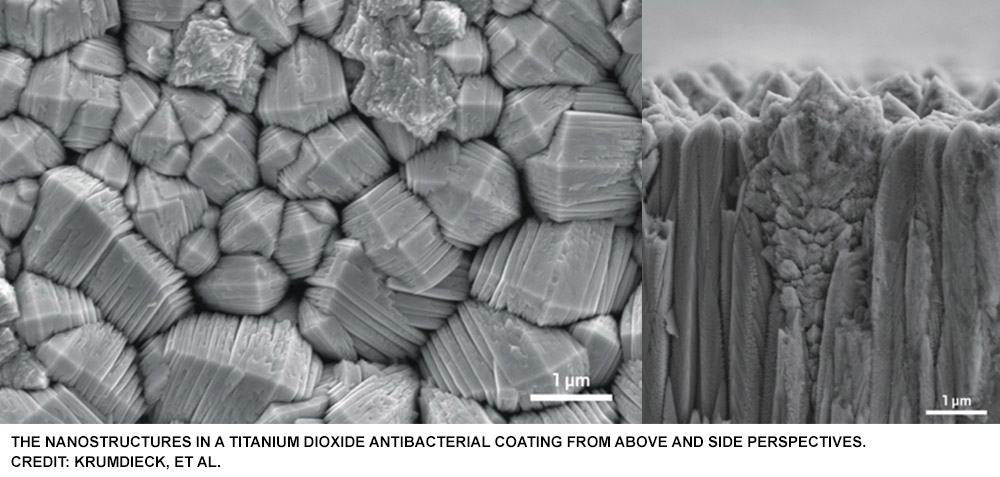

The new coating, which kills bacteria under visible light, is made of intricate nanostructures of titanium dioxide, which is made using chlorine chemistry. The coating has promise in the “big market for effective, low-cost coatings that can kill bacteria on hospital surfaces without contributing to the development of antibiotic resistance,” notes C&EN.

In ultraviolet light, titanium dioxide breaks down water vapor in the air to produce free oxygen radicals that attack whatever is on the surface. “This includes organic material, such as the membranes of bacterial cells,” hence the use of titanium dioxide on self-cleaning glass, says the newsletter. However, ultraviolet-activated titanium dioxide coatings are not practical for hospital use, and lead author Susan Krumdieck of the University of Canterbury in New Zealand is quoted as saying that “the hunt has been how to shift this magic over into the visible light spectrum.”

“TiO2 is famously bright white or transparent, but one day the coating came out all black,” Krumdieck says in a press release. The researchers knew they had a new material “due to the strange nanostructures” they saw and the “striking black color.”

Krumdieck has developed a pulsed chemical-vapor deposition technique that she and colleagues use to grow the new coatings directly on stainless steel. This uses an ultrasonic atomizer to make a fine mist of a titanium dioxide precursor that is sprayed in pulses onto the steel, increasing the growth rate of the titanium dioxide crystals. Krumdieck says the coating’s surface area is 100 times greater than earlier titanium dioxide coatings made with nanoparticles, generating more bacteria-killing free oxygen radicals. The coating has been applied to stainless steel doors and faucet handles; the team expects the method will also work on other metals and on glass.

The scientists tested the coating’s antimicrobial activity by spreading E. coli culture on a sample and exposing it to UV and white light from a commercial 1500-lumen lamp for four hours. “UV exposure killed all the bacteria every time, while visible light killed over 99% of the bugs,” states C&EN. Krumdieck is quoted as saying, “Visible light activity is not as complete as UV but beats the international standard for antibacterial materials by an order of magnitude.”

The team is now working with several companies to complete the engineering development science needed for designing and scaling up for advanced manufacture. “Interested international companies are watching progress and hoping the black TiO2 will soon be warding off germs on hospital bed rails and door handles around the world,” concludes the release.

Citation:

Krumdieck, S. P., Boichot, R., Gorthy, R., Land, J. G., Lay, S., Gardecka, A. J., . . . Bishop, C. M. (2019). Nanostructured TiO2 anatase-rutile-carbon solid coating with visible light antimicrobial activity. Scientific Reports,9(1). doi:10.1038/s41598-018-38291-y

Image creative commons license available here. Minor modifications to left image; right image unaltered